1: The cost is high, the initial investment is more than 100W, and the follow-up cost is unknown;

2: It is difficult to break through the technical difficulties of product integration, there are many devices on the market, and it is difficult to achieve the interconnection and communication of all devices and data sharing without a large number of experts with industrial background;

3: Small and medium-sized enterprises can only do the application of their own related vertical industries, and they have little ability and experience in big data analysis, so they can't convert a large number of data into productivity;

4: Industrial Internet must be an open platform. How to make it safe and open is also a difficult task;

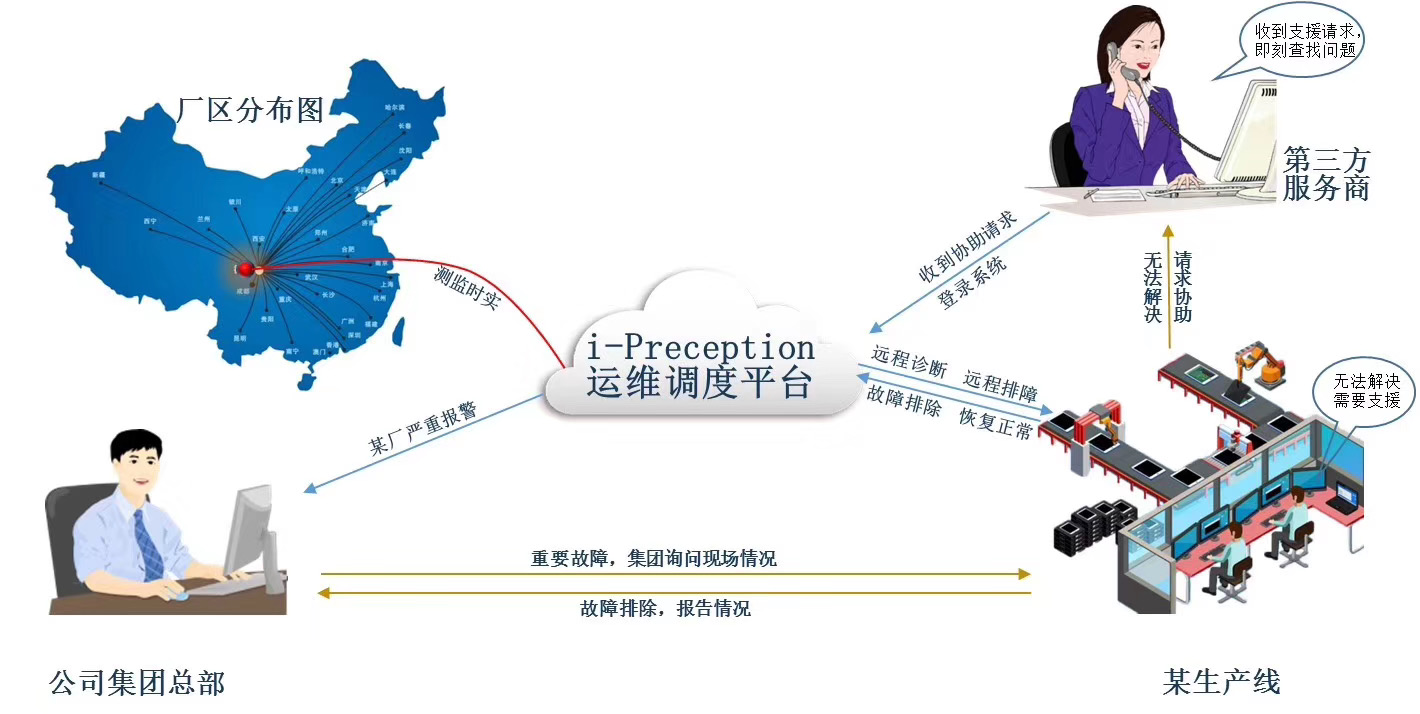

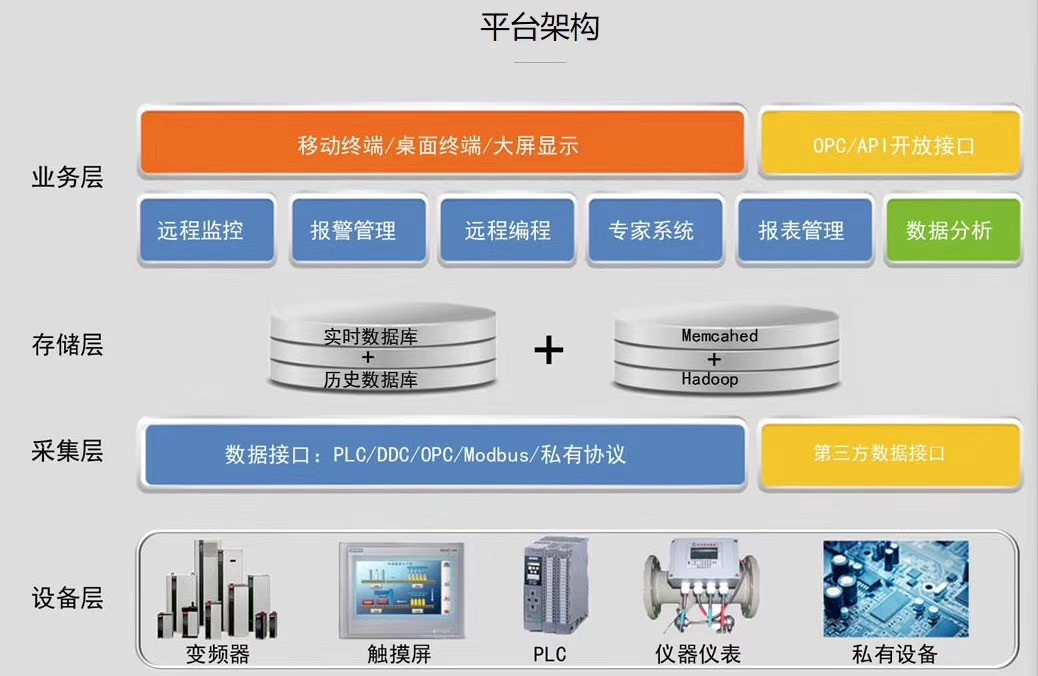

The i-concept industrial cloud platform provided by our company provides a complete solution, which is to provide small and medium-sized manufacturing enterprises with a low threshold, fast, plug and play ability to use big data and Internet of things technology. The solution combines the most advanced Internet of things, cloud computing, sensors, automatic control and other technologies to display the real-time operation of all the connected devices in the browser or mobile app client, at the same time, it provides strong data support for equipment operation and maintenance, after-sales service, equipment upgrade, fault alarm, troubleshooting and other aspects through statistical analysis of big data, so as to further refine Manage the whole operation, management and service process of the production system in a detailed and dynamic way;